Practical strategy for solving the problem of

pressure switch not jumping

In industrial production and the operation of various mechanical equipment, pressure switches play a crucial role. They can automatically control the start and stop of equipment according to changes in system pressure, thereby ensuring the normal operation and safety of the system. However, when the pressure switch fails to trip, it can bring many inconveniences and potential risks to production. Below are some practical strategies to solve the problem of pressure switch not tripping.

Firstly, check if the pressure source is functioning properly. Sometimes when the pressure switch does not trip, it is not a problem with the pressure switch itself, but rather an abnormality in the pressure source. For example, pressure pump failure, pipeline leakage, etc. may cause the system pressure to fail to reach the action value of the pressure switch. Real time monitoring of system pressure can be achieved through devices such as pressure gauges to determine whether the pressure source can provide sufficient pressure. If problems are found with the pressure source, the pressure pump should be repaired or replaced in a timely manner, and the pipeline leakage point should be repaired to ensure that the system pressure can rise to the set value normally.

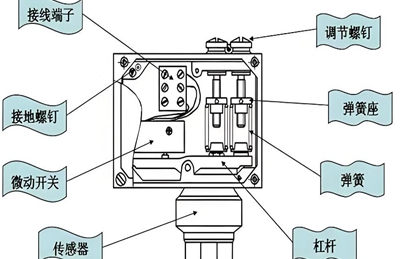

Secondly, conduct a comprehensive inspection and testing of the pressure switch. In addition to the mechanical faults mentioned earlier, it is also necessary to check whether the internal circuit of the pressure switch is normal. The output signal of the pressure switch can be measured using tools such as a multimeter to determine whether it can output an electrical signal normally when the pressure reaches the set value. If problems are found in the circuit, such as short circuits, open circuits, or damaged electronic components, they need to be repaired or replaced in a timely manner. In addition, pressure switches can be simulated and tested by manually adjusting the pressure source to observe the operation of the pressure switch and further determine whether it is working properly.

Furthermore, consider whether the selection of pressure switches is appropriate. Different application scenarios have different performance requirements for pressure switches, and improper selection may also result in the pressure switch not tripping. For example, in high-pressure and high-frequency operating situations, if a pressure switch with low pressure resistance and low lifespan is selected, it is prone to malfunction. Therefore, when choosing a pressure switch, it is necessary to select the appropriate model and specifications based on actual application needs to ensure that it can meet the working requirements of the system. At the same time, it is important to choose brands and products with reliable quality to avoid malfunctions caused by product quality issues.

In addition, regular maintenance and upkeep of pressure switches are also very important. Regularly clean the casing and pressure pipe of the pressure switch to prevent dust, dirt, and other impurities from entering the interior of the pressure switch and affecting its normal operation. At the same time, it is necessary to check whether the installation of the pressure switch is firm to avoid loose connections due to vibration and other reasons. In addition, the pressure switch can be regularly calibrated to ensure the accuracy of its set value.

In short, solving the problem of pressure switch not tripping requires comprehensive consideration of multiple factors. By inspecting and handling the pressure source, pressure switch itself, selection, and maintenance, the problem of pressure switch not tripping can be effectively solved, ensuring the normal operation of equipment and smooth production.

#Keywords:

pressure switch; Not jumping; Pressure source; Inspection and testing; Selection; Maintenance